Powder Transfer Printing using Computational Method

Backgrounds and Motivations

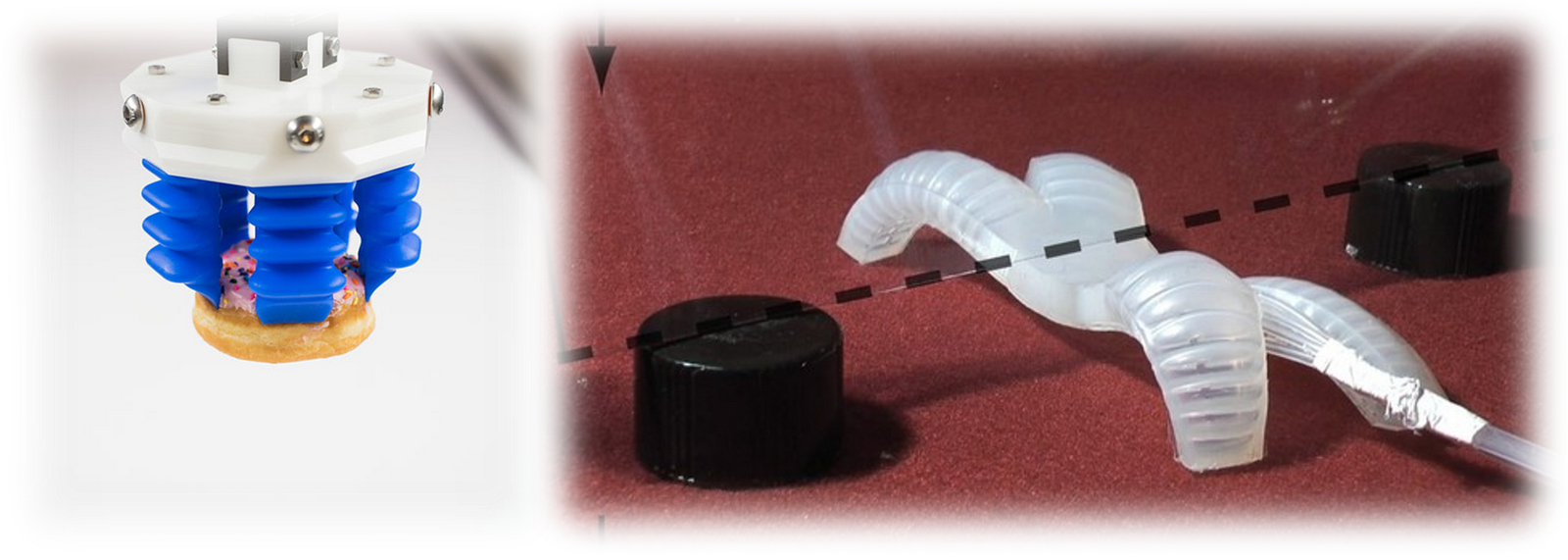

Soft Robotics is in the spotlight because it can perform a unique skill that “hard” robots can’t.

However, an accurate sensor locating technique is necessary for advanced soft robots, which is very hard because of their complex surface.

Figure 1. Examples of soft robotics

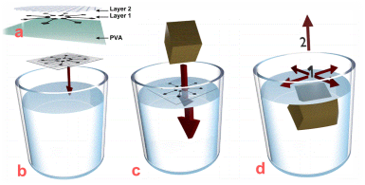

Water Transfer Printing (WTP) is a well-known technology for transferring color images to a 3D surface.

Recently, WTP technique was suggested as a solution to sensor locating problems in soft robotics (Borgne et al., ACS 2017).

Figure 2. water transfer printing technology in manufacturing of conformal electronics (Borgne et al. ACS 2017)

However, this technology has a significant problem. The position of sensors or circuits on the water varies with time.

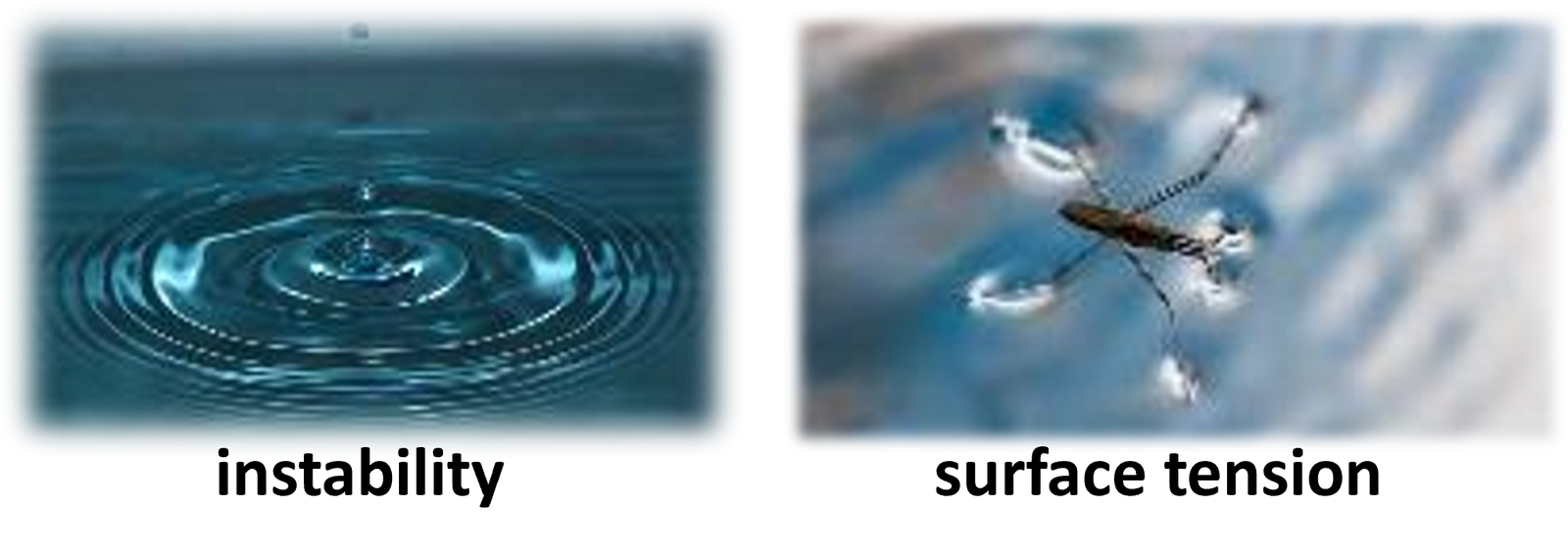

This problem occurs due to the instability and surface tension of water.

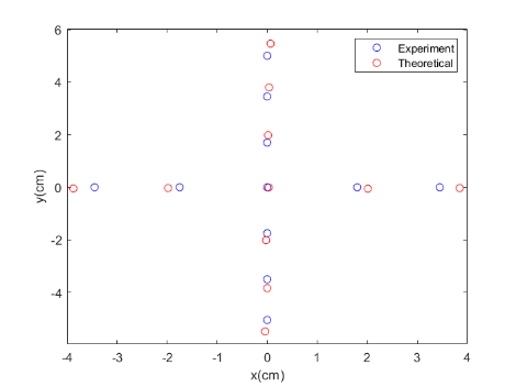

Figure 3. Disadvantages of water

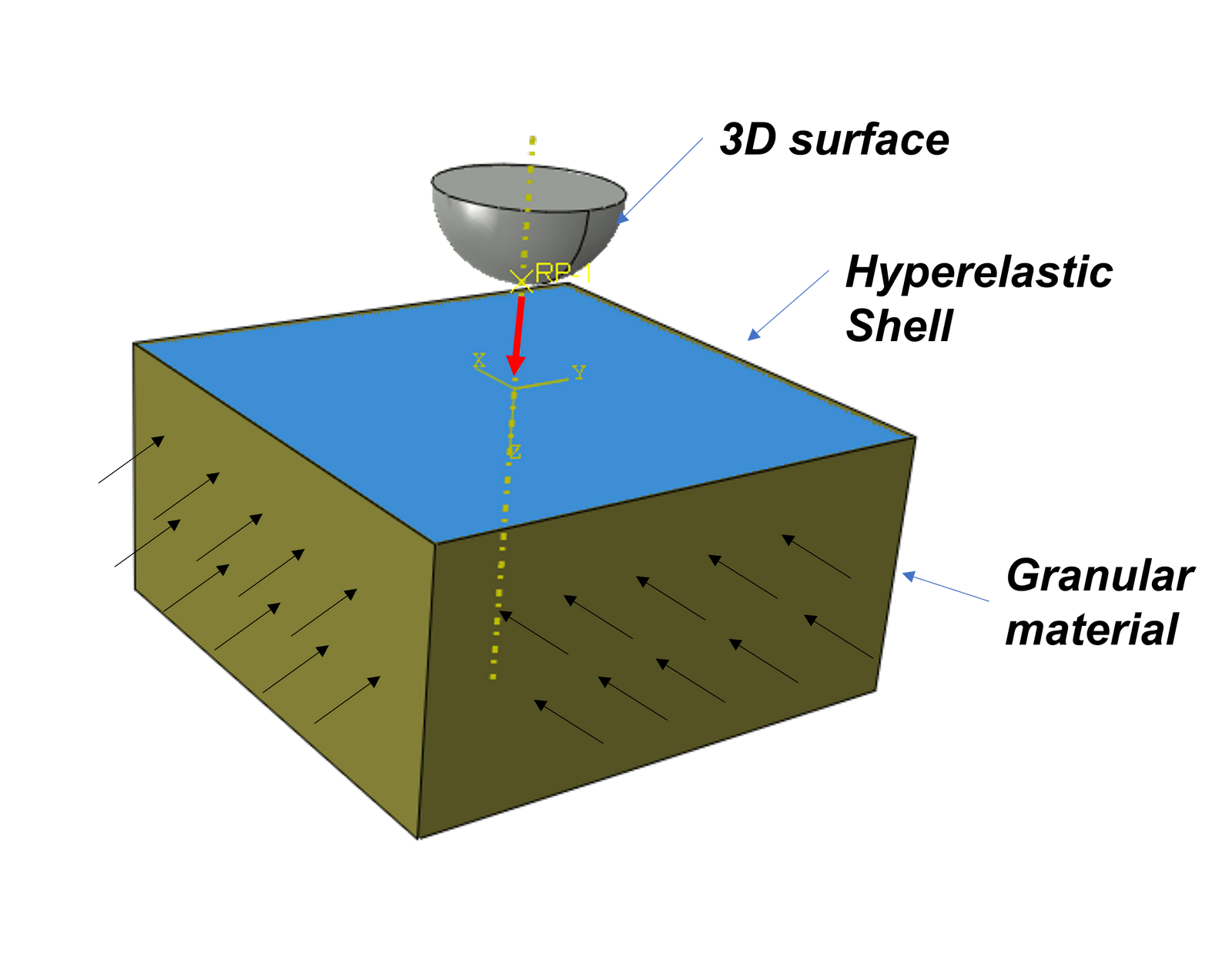

Therefore, we solved the problem by replacing water with granular materials and named it "powder transfer printing".

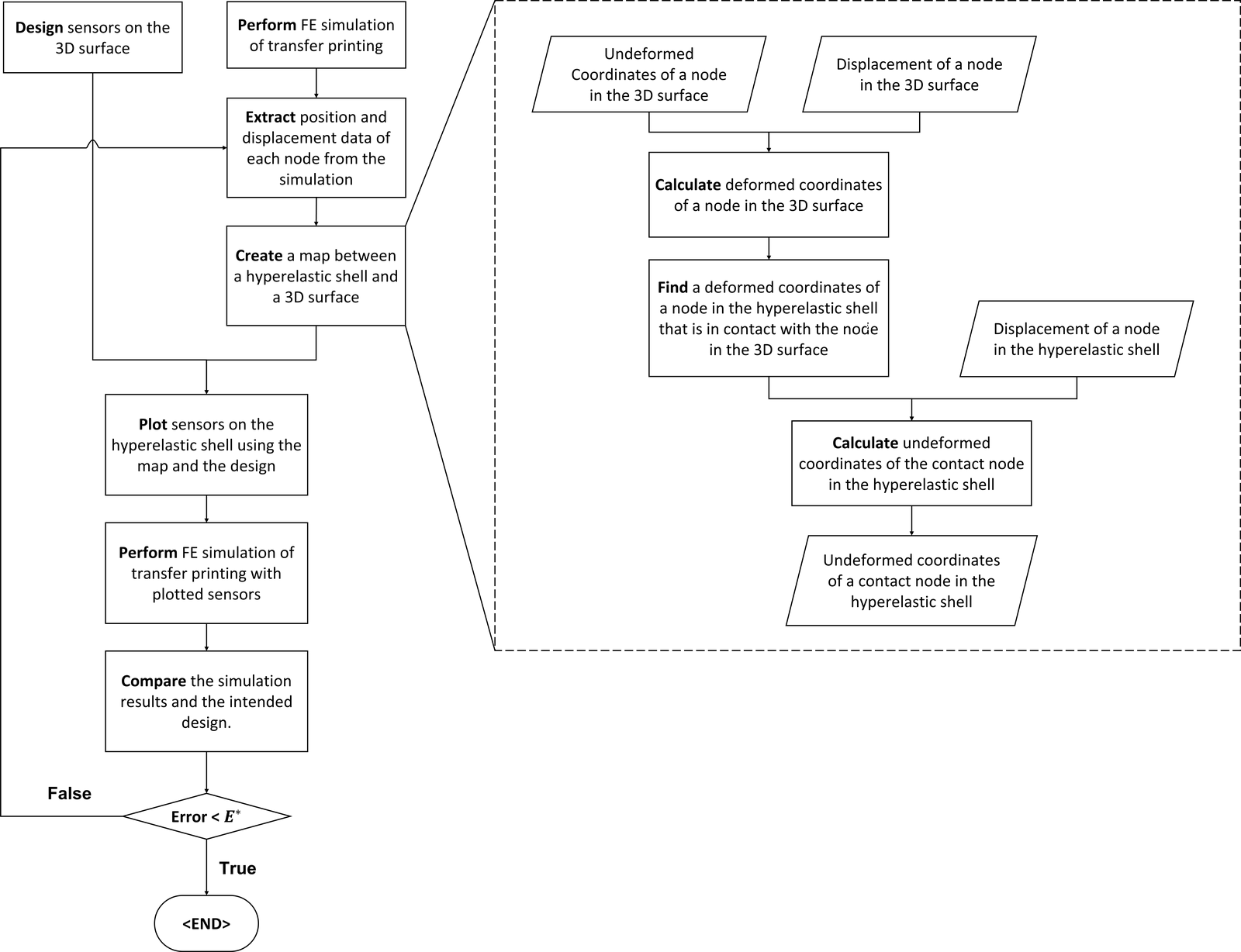

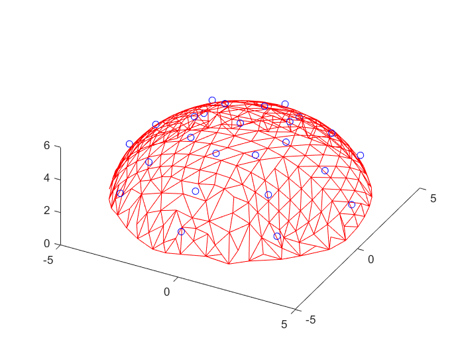

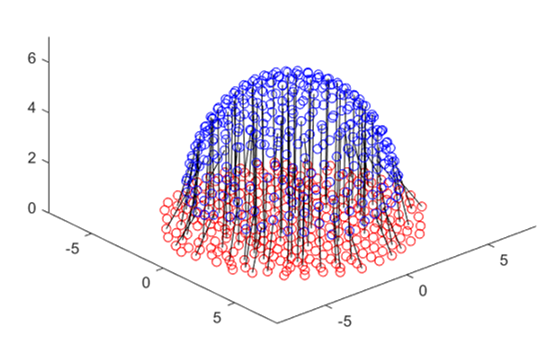

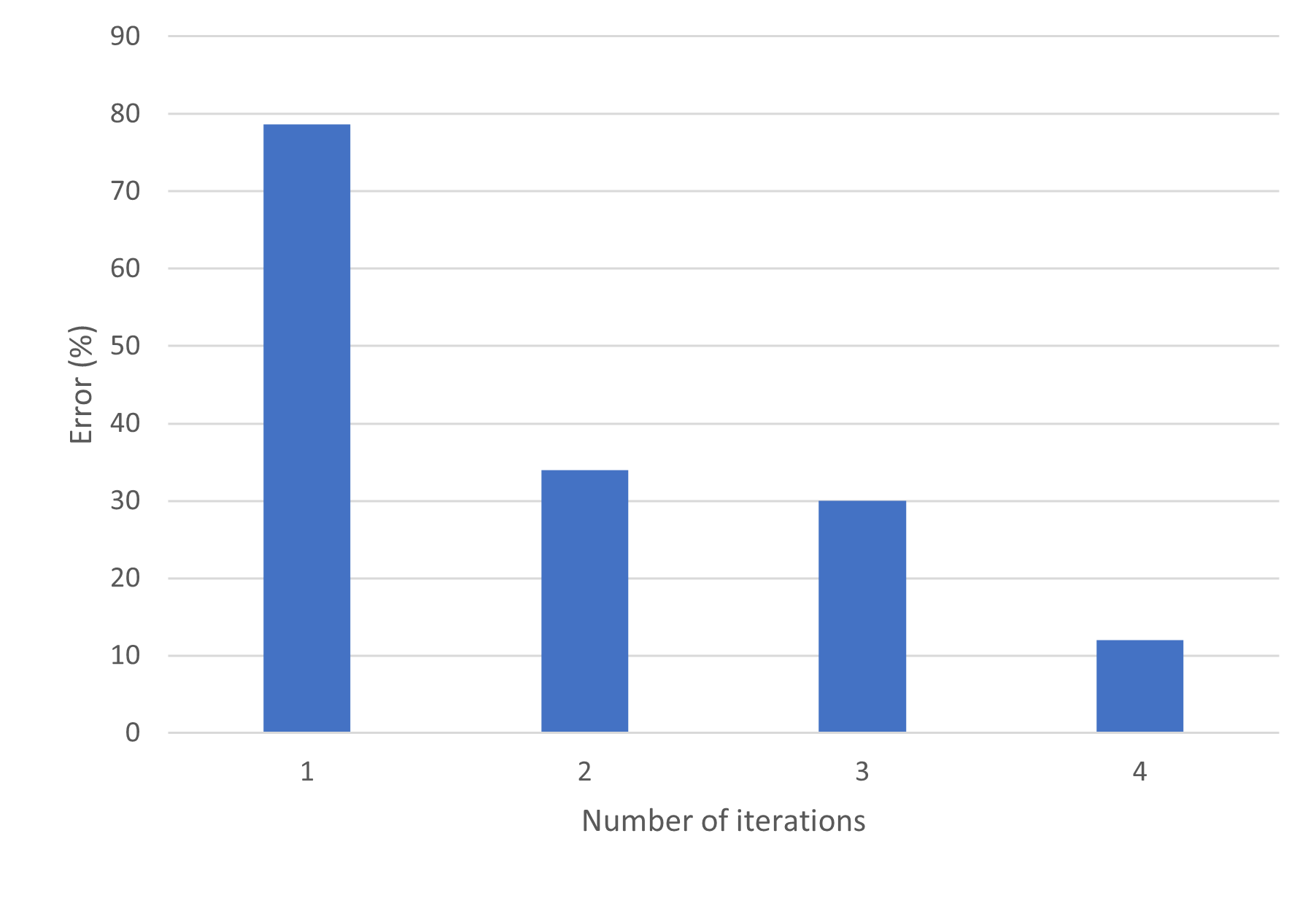

Also, we adapted a computational method to improve precision of sensors' location after transfer printing.

First, we replaced water with granular materials. Granular materials easily deform and show almost perfect plastic behavior, so they are an ideal substitute for water. Also, granular materials have negligible surface tension and are much more stable than water, so using these would not show the problem mentioned above.

Second, we adapted the computational method. Zhang et al. have already developed a computational method for WTP. However, the response of granular materials to stress is more complex than water. So we devised a new methodology to computationally predict the sensors' location after transfer printing.