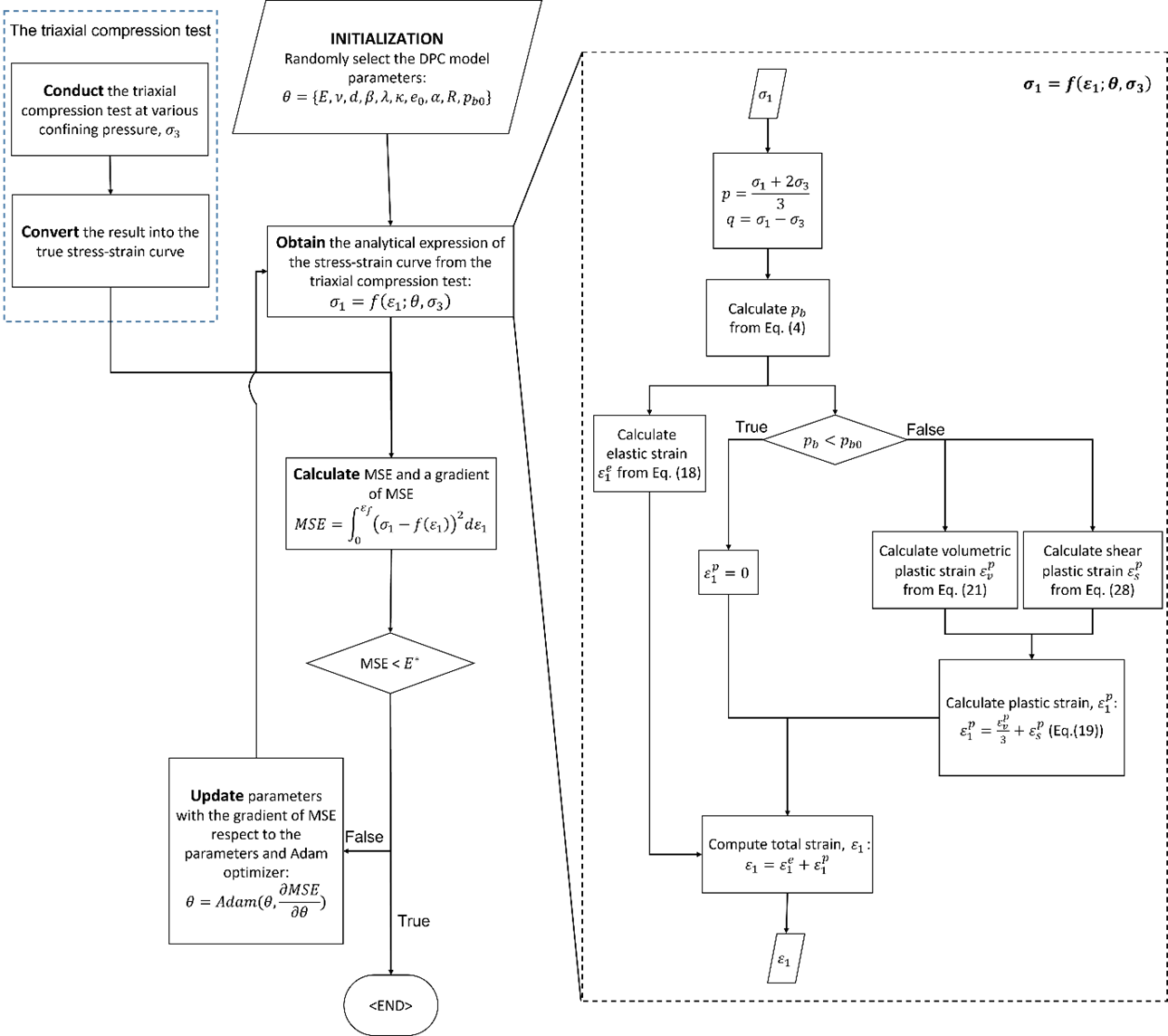

Theoretical Approach

Figure 1. Overall Algorithm

Fig. 1 describes the overall methodology

used in this study.

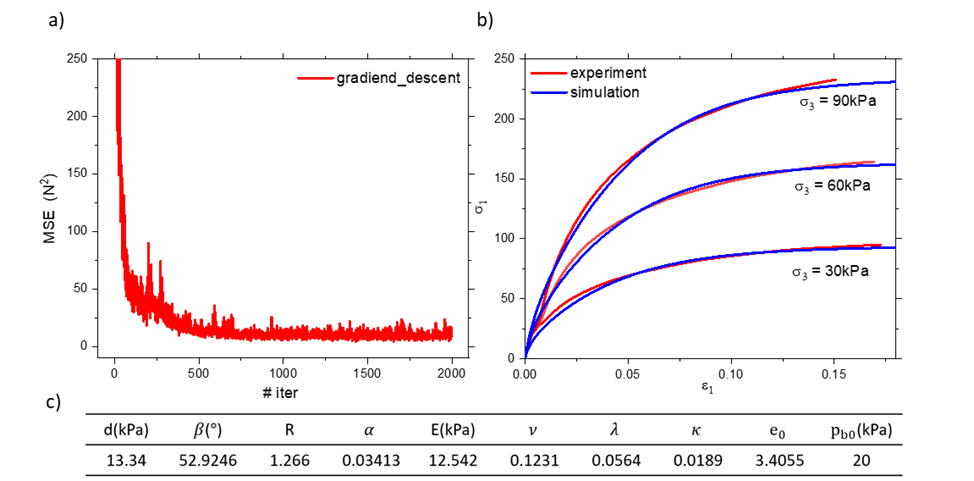

In the beginning, the parameters are randomly selected.

After selecting random parameters, the analytical expression calculates the stress–strain

curve—the result of the triaxial compression test—from the selected parameters.

Afterward, the error between the experiment results and the calculation is

computed. This study used mean squared error (MSE).

If

MSE is larger than an objective value, the gradient descent algorithm updates

the parameters and repeats the whole process until MSE becomes lower than the

objective value.